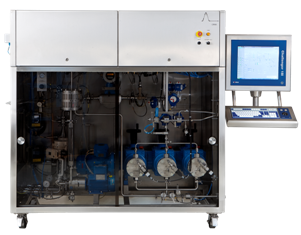

MPLC systems (10-30 bar)

Peak Biotech MPLC systems are available for

chromatograpy applications, in pilot to production scale.

The systems are designed for continues or batch production and in

complianc with all relevant standard within the pharmaceutical and

biotech industry.

The systems are custom deisgned to fit customer requiremenst with

many different configurations and options.

The systems are controlled by PeakChrom software speciel designed

for chromatography process and the software is in compliance with

CFR Part 11, GAMP5 and S.88.

Systems are available in wiht linear gradient, step gradient or

isocratic versions.

Specifications

Flow rate in range 6 - 10000 l/h.

Pressure range up to 30 bar.

Automation / Control system

Fully automated with Peak Control Software, the software is in

compliance with all relevant standards like CFR Part 11, GAMP 5 and

S.88.

Designed for fully automated batch control. The software is fully

documented and tested.

For more details click automation.

Gradient performance

High accuracy gradient mixing loop with feedback from

conductivity, NIR or other inline instrument.

Inline mixing from 0 - 100% with accuracy below 1% of FS (full

scale).

Inline degassing gradient loop.

Systems are avaiable in gradients or isocratic versions.

Materials and construction code

Standard systems are fabricated in Stainless Steel.

All used components are fully documented and tested.

Systems are available in Explosion proof versions that fulfill the

requirements for Europe (ATEX) or US (Class One Div xx). Systems

for Europe are CE marked.

Designed according to ASME BPE.

Sanitary design

Systems are designed with focus on sanitary design.

Connections are sanitary design with sealings in

PTFE or EPDM.

Flexible

The systems are mobile and can be moved around within the

facility.

Easy installation and connection for quick start-up.

Designed for production and 24h running.

Short down time and low maintenance cost.

Reliable and reproducible.

Qualification, validation and services

Peak Biotech offer fully documented qualification

pakage (e.g. FAT, SAT, IQ, OQ & PQ) for all equipment.

For more details click qualification.

Standard configuration

Diaphragm pump 3 heads.

Stainless Steel piping and instruments.

4 Inlets, 2 used for gradient performance.

1 product inlet.

5 fraction outlets.

Conductivity instrument for gradient feedback.

Options

• Extra buffer inlets (4 is standard)

• Extra fraction valve (5 is standard)

• Conductivity after column

• Pressure after column

• Temperature before and after column

• Alternative pump type

• Magnetic flow meter

• Recycle loop

• Filter module, in-line

• Sample loop for small amount of product orcolumn testing

• Nitrogen blowing of product lines

• Heat exchanger

• Load pump

• Valve feedback

• And many others